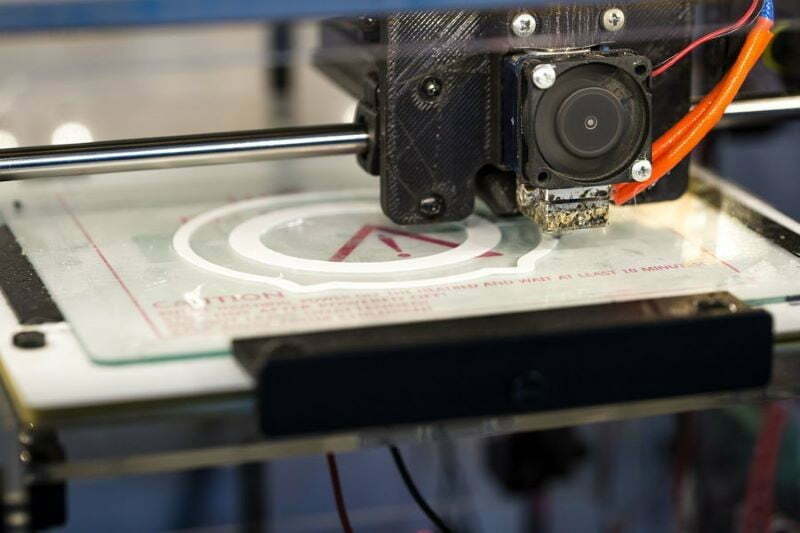

Rapid Prototyping (RP) can be characterized collectively of procedures used to rapidly create a scale model of a section or get together utilizing three-layered PC supported plan (CAD) information.

Rapid Prototyping Tips

What is regularly viewed as the primary RP strategy, Stereolithography, was created by 3D Systems of Valencia, CA, USA. The organization was established in 1986, and from that point forward, various different RP strategies have opened up.

Rapid Prototyping has additionally been alluded to as strong freestyle producing, PC robotized fabricating, and layered assembling. RP has clear use as a vehicle for representation.

What’s more, RP models can be utilized for testing, for example, when an airfoil shape is placed into an air stream. RP models can be utilized to make male models for tooling, for example, silicone elastic molds and speculation projects.

Sometimes, the RP part can be the last part, however regularly the RP material isn’t solid or adequately exact enough. At the point when the RP material is reasonable, profoundly tangled shapes (counting parts settled inside parts) can be created as a result of the idea of RP.

1. Select Precise Assembling Process

Metal Parts

Metal models are generally handled by CNC or metal 3D printing. Albeit metal 3D printing is great for a few certain models, however it isn’t reasonable for creation as a rule.

However contempory innovation is propelling, it is still excessively sluggish and exorbitant for bigger volumes exccept complex calculations and lightweight parts.

Most metal models are handled by CNC, which is a decent method for growing the volume due to the interest increments over the long haul.

For large scale manufacturing, pressure bite the dust projecting can be thought about.

This is the quickest and most efficient method for assembling enormous quantities of indistinguishable metal parts.

Kindly note that PDC ought to observe a few plan guidelines for assembling and a creation device should be contributed. However, this cost can be covered by a huge creation request.

Plastic Parts

Assuming the model is made of plastic, it is probably going to be made by 3D printing, CNC machining or polyurethane vacuum projecting. The ideal arrangement is plastic infusion forming for bigger volumes of plastic parts.

When utilizing fast prototyping severe plan rules should be submitted to very much like strain pass on projecting.

These incorporate the utilization of ribs and supervisors, least divider thickness aspects, draft point, door area, sprinters, thimble and numerous different contemplations.

Accordingly, item engineers should ensure that their arrangements consider the extra expenses and time to advertise associated with the change starting with one cycle then onto the next.

2. Set Out A Rundown of Materials

The model normally includes a couple of finished parts, which are esteemed per complete unit. When entering the creation stage, each thing in the gathering should be counted plainly.

Each measure of nuts, fasteners and screws, elastic buttons or metal clasps, or even paint or paste, should be determined as a different expense.

More creation lines implies a more intricate store network, so it is useful if plan as basic as could really be expected. At long last, a point by point BOM (a huge expense driver) can assist you with assessing the work cost.

3. Select The Proper Material

Some of the time models are made of exorbitant or extraordinary materials. This is done to make it a show, to help showcasing or financing events.

However exceptional materials are not a decent decision for large scale manufacturing, so more normal unrefined components will be utilized to supplant them.

Normal unrefined components will be less expense, simpler and quicker to get. In particular, producers have really working involvement in stock materials, which will make it more straightforward to control process boundaries to acquire more solid outcomes.

4. Select The Precise Surface Treatment

The presence of model looks astonishing in the wake of being painstakingly sanded, cleaned and hand-painted with custom tones. However, for a huge scope, is it doable?

Fine surface treatment frequently requires a ton of consideration in subtleties and fastidious manual work, which isn’t dependably imaginable in large scale manufacturing.

Assuming you need a particular cleaning, we propose to find computerize ways or demand a couple of cleaning rather than various cleaning.

For aluminum parts, anodizing is an appealing and entirely sturdy surface treatment strategy. Parts can be handled in bunches on a case by case basis without a base amount restricted.

5. Foster Confirmation and Testing Plan

Different with models, parts for business utilization should be confirmed by different wellbeing and administrative projects.

It relies upon many elements, remembering the climate for which the item is utilized, power is utilized or not, and the country where it is sold.

You should be prepared to send the completed item to various associations for confirmation, and ascertain the time and cost of this essential advance. (GP)